Are you looking to create a comfortable and durable sleep surface in your bedroom? If so, this guide will show you how to make a foam mattress from scratch. From selecting the right materials to constructing your mattress, this step-by-step guide will walk you through the entire process of creating a foam mattress that will provide you with a good night’s sleep.

Materials Needed

For creating a comfortable and durable foam mattress, the following materials are necessary:

- Foam: High-density foam should be used for the mattress core. The thickness of the foam should be at least 5 inches.

- Fabric: Choose a breathable and sturdy fabric for covering the foam.

- Adhesive: A water-resistant adhesive is required for attaching the fabric to the foam.

- Thread: A strong thread is necessary for sewing the fabric.

- Needle: A needle of the right size should be used for attaching the fabric to the foam.

- Padding: Padding material may be required to provide extra cushioning and comfort to the mattress.

These materials are essential for making a foam mattress that is both durable and comfortable.

Preparing the Foam

- Choose the Right Foam: Select a foam that is specifically designed for mattress use, such as latex, memory foam, or polyurethane foam. It should be thick enough to provide support and be of a quality that will last for years.

- Cut to Size: Measure the desired size of the mattress and then cut the foam to fit. It should be slightly larger than the frame to ensure a snug fit.

- Sand & Smooth the Edges: Use sandpaper to smooth out any rough edges and ensure a comfortable surface.

- Wrap the Foam: Wrap the foam in a thin layer of batting to give it a more finished look and provide an extra layer of protection.

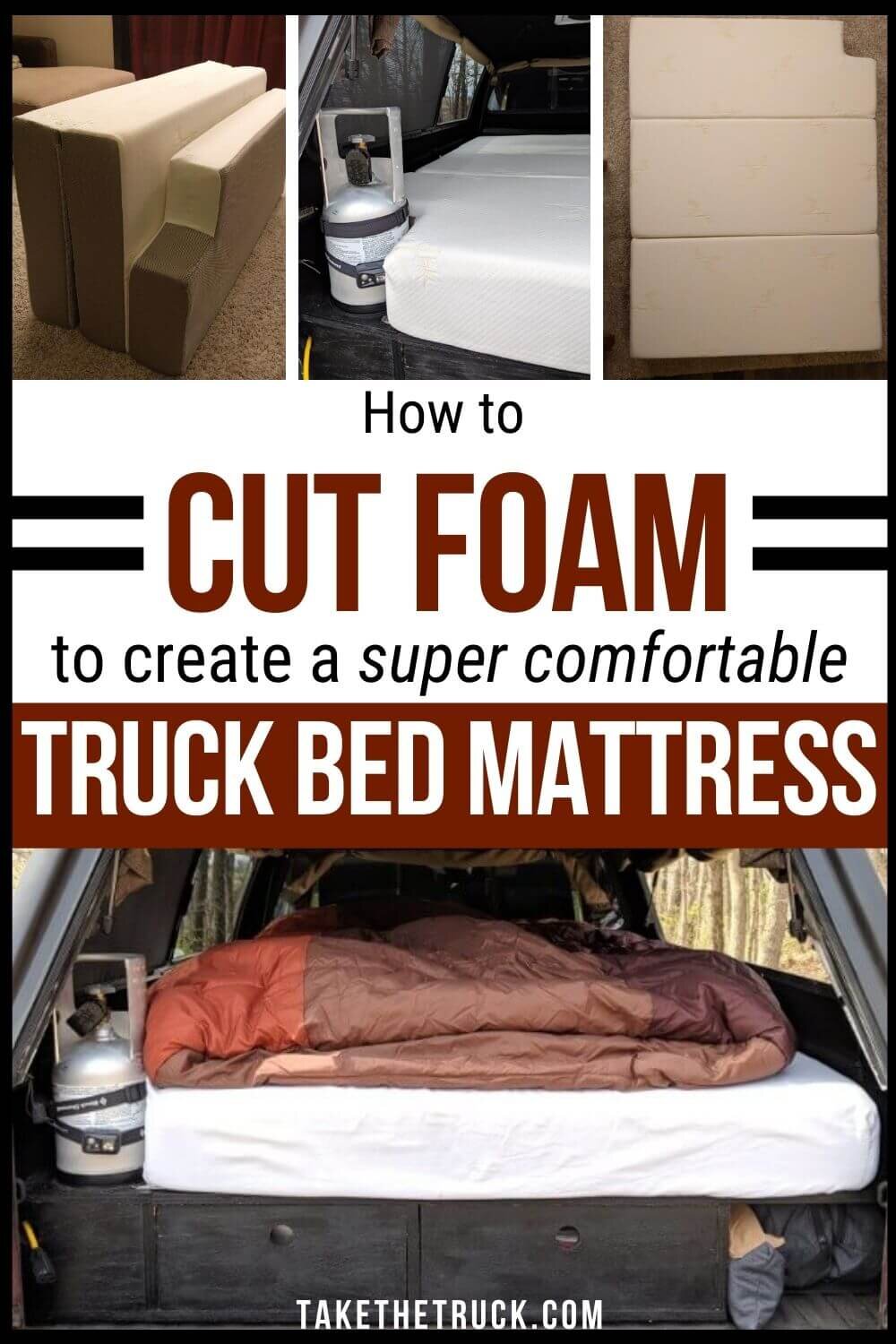

Cutting & Shaping the Foam

- Density Matters: Foam density affects the overall support and comfort of the mattress. A higher density foam will provide more support while a lower density foam will provide better cushioning.

- Cutting: Foam can be cut with a knife or electric saw. A knife is best for small, precise cuts, while an electric saw is better for larger, more complex shapes.

- Shaping: Foam can be shaped by hand or with a power tool. Hand shaping is best for simple curves, while power tools are better for more intricate shapes.

- Sanding: Sanding is an important step in shaping foam. It helps to smooth out any rough edges and create a more even surface.

- Gluing: Foam can be glued together using a polyurethane-based adhesive. This is especially helpful when creating complex shapes or when joining multiple pieces of foam together.

Making the Mattress Cover

Once the foam mattress has been assembled, the next step is to create a cover for it. The cover acts as a protective barrier, keeping the foam mattress clean and free from dust and dirt. It also adds an extra layer of comfort when lying on the mattress.

To make a mattress cover, you will need to purchase fabric from a fabric store. Measure the mattress and purchase enough fabric to cover the entire surface. Cut the fabric to the correct measurements and then lay it out on a flat surface. If you are using a patterned fabric, make sure to position it so that the pattern will be aligned correctly on the mattress.

Once the fabric is cut and laid out, use an industrial-grade sewing machine to sew the fabric together. Make sure to make strong, secure stitches to ensure that the cover will be able to withstand regular use.

Once the cover is sewn, insert the foam mattress and zip the cover closed. The mattress is now ready for use.

Assembling The Mattress

- Lay the mattress foundations on the floor. Place the two halves of the mattress foundations on the floor. You should have the two halves laid out side-by-side with the open side of the foundations facing up.

- Attach the two halves of the mattress foundations. Use the screws and bolts provided with the kit to attach the two halves together. Make sure that the screws are tightened properly and that the two halves are securely attached.

- Place the foam mattress on top of the foundations. Carefully place the foam mattress on top of the foundations. Make sure that the mattress is centered and that it is lying flat.

- Secure the mattress to the foundations. Use the screws and bolts provided with the kit to secure the mattress to the foundations. Make sure that the mattress is held firmly in place and that the screws are tightened properly.

- Add the mattress cover. Place the mattress cover over the mattress and secure it to the foundations using the straps and buckles provided with the kit.

Finishing Touches

| Step | Description |

|---|---|

| 1 | Lay the fabric covering on the top of the mattress. Secure the fabric with a staple gun. |

| 2 | Cut the fabric around the edges of the mattress using a sharp pair of scissors. |

| 3 | Apply a quilted mattress pad to the top of the mattress for added comfort. |

| 4 | Place the mattress on the bed frame and make sure it fits snugly. |

Add a layer of protection to your mattress with a mattress cover. This will help prevent dirt, dust, and spills from getting into the mattress and compromising its comfort and durability. Finally, rotate the mattress every three months to ensure even wear and tear.

Testing the Mattress

Once the mattress has been constructed, it is important to test it for comfort and durability. This is best done by lying on the mattress and noting the areas of pressure and support. If a mattress is too soft or too firm, it may not provide adequate support for the body. Additionally, the mattress should be tested for any areas of discomfort that may arise from incorrect construction or improper materials.

Durability Test

The durability of the mattress should be tested to ensure that it will stand up to regular use and wear and tear. To do this, it is recommended to perform a few simple tests:

| Test | Description |

|---|---|

| Weight Test | Place a heavy object on the mattress and check for any signs of sinking or indentations. |

| Resilience Test | Place your hand on the mattress and press down. If it bounces back quickly, the mattress is resilient. If not, it may need more support. |

| Edge Firmness Test | Sit or lie on the edge of the mattress and check for any areas of discomfort. |

If the mattress passes these tests, it is ready for use. If any areas of discomfort or instability are noticed, adjustments should be made to the mattress before it is used.

Frequently Asked Questions

What Materials are Needed to Make a Foam Mattress?

To make a foam mattress, you will need foam, upholstery fabric, batting, zippers, tape measure, and scissors. Foam can be purchased in different densities, thicknesses, and firmness levels. Upholstery fabric is a durable material that is used to cover the foam and batting. Zippers are used to secure the fabric to the foam. A tape measure and scissors are needed to accurately measure and cut the foam, fabric, and batting.

How long does it take to complete the mattress making process?

The mattress making process can take anywhere from a few hours to a few days, depending on the type of mattress being made. Foam mattresses are generally the quickest to make, taking up to a few hours to complete, while hybrid mattresses can take up to a few days. The amount of time required to make a mattress will also depend on the complexity of the design, the quality of materials used, and the craftsmanship of the maker.

What type of foam should be used for the mattress?

High-density foam is the best choice for mattresses. It is firm and supportive, yet still comfortable. Look for foam with at least a 2.5-3.0 lb/ft3 density rating. Memory foam and latex foam are also popular options and provide extra cushioning and support. Avoid low-density foam as it is often too soft and will not provide adequate support.

Are there any safety precautions to consider when constructing a foam mattress?

Yes. When constructing a foam mattress, there are several safety precautions to consider. These include:

- Wearing protective gear such as gloves, goggles, and a dust mask to protect against any particles or chemicals in the foam.

- Ensuring proper ventilation while working with foam, as some foams can produce fumes.

- Following all instructions on the foam product packaging carefully.

- Avoiding the use of power tools when cutting the foam, as this can create dangerous particles.

- Ensuring that the mattress is properly supported on a sturdy frame.

By following these safety precautions, you can ensure that your foam mattress is safe and comfortable for years to come.

Is it Possible to Customize the Size of the Mattress to Fit a Particular Bed Frame?

Yes, it is possible to customize the size of a foam mattress to fit a particular bed frame. You can have the foam cut to the exact size of the bed frame, and this will ensure a perfect fit. This will also help to extend the life of the mattress, as it will not be prone to sagging or shifting. It is important to take measurements of the bed frame before ordering the foam so that you get the perfect fit.

Conclusion

Creating your own foam mattress is a great way to get quality sleep without spending a fortune. With the right tools and materials, this step-by-step guide can help you make a comfortable and durable mattress that will last for years. With a little patience and effort, you can have a mattress that is tailored to your own specific needs and preferences.

References

- “Sleep Products Safety Council,” beddingindustry.org

- “Foam Mattress Manufacturing,” www.osha.gov

- “Design and Construction of Mattresses,” uwaterloo.ca